It can be manufactured to handle vibrations, shock, and other industrial conditions. It has fewer parts such as wiring of both circuits embedded on a single board. It has various advantages of flexible ad rigid PCB. Multiple layers of flexible PCB attach to rigid PCB layers to make this. The combination of rigid and flexible PCB is Rigid-Flex PCB. Flexible PCB board manufacturer in china are tracing the circuit with graphene like material which is suitable for flexible substrate. Bulky and heavy components replace with Flexible PCB. The applications where weight and space are very important, Flexible PCB are useful. Flexible PCB are expensive as compare to Rigid PCB board. The substrate fits itself into various places to reduce the damage of components. This type of PCB is a printing on flexible substrates and comes in various designs like single, double and multi-layer PCB.

It is very useful for different works such as: Rigid PCB board manufacturer in china are focusing on quality, price and durability. Especially, they also produce low electronic noise. In the latest era motherboard is the best example of these PCBs. So, the life of the components increases. This reduces the flexibility and bending of the board. In general, the solid substrate is used for the fabrication of Rigid PCB. So, they can save more energy and easily recycled. However, Aluminum boards are also non-toxic and environment friendly. In short, Aluminum is the only metal on the earth which is easily mined. They can reduce the damage and also cheap. Hence, the aluminum-backed PCB is more durable than the fiber glass PCB. Moreover, the greater durability and lower cost for complex and heavy-duty performance. The improvement in thermal and heat dispersion, this type of board is helpful for complex projects. Aluminum backed PCB cools faster than other PCB. It shows better thermal efficiency and can easily emit the heat away from the circuit. Due to this, Aluminum backed PCB is very useful for high performance.

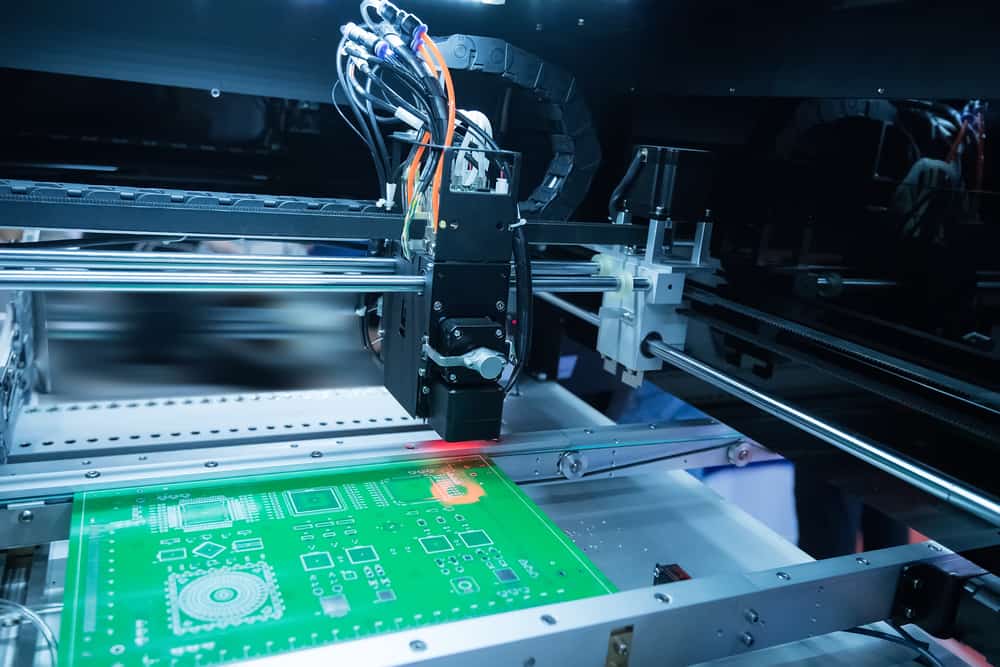

They give several advantages over fiberglass board. To summarize, various advantages of multi-layered are below.Īluminum backed PCB is also popular because of aluminum or copper surface. MOKO Technology is the best company for multi-layer PCB board manufacturer in china. Medical equipment and also servers use multi layer boards. Specially, these multi layers boards have 3 – 10 layers depending on electronic applications. Likewise, in the double-layer and multi-layer board, there are two methods: surface mount and through-hole. The separation of layers uses insulating material.

Multi-Layer PCBĪccording to the need and applications, the multi layer can be developed which consists of three or more layers. Further, the surface mount has advantages such as more tasks, fast performance, and less weight. In comparison, by hand drilling holes into the board and connects the components by soldering. Therefore, the process which allows directly soldering the component into the board is surface mount technology. In double-sided boards, electronic components embed with two methods: through-hole or surface mount technology. These are similar to the single sided PCB and have electronic components on both sides of the substrate. However, these boards are widely useful in simple electronics. Single sided means, all components and parts are placed on one side of the board. They are very famous for hobbyist and the production of these is simple and cheap. They are circuit boards that comprise base or substrate surface. PCB Assembly for New Energy, Payment Devices.

0 kommentar(er)

0 kommentar(er)